| Availability: | |

|---|---|

| Quantity: | |

Product Description

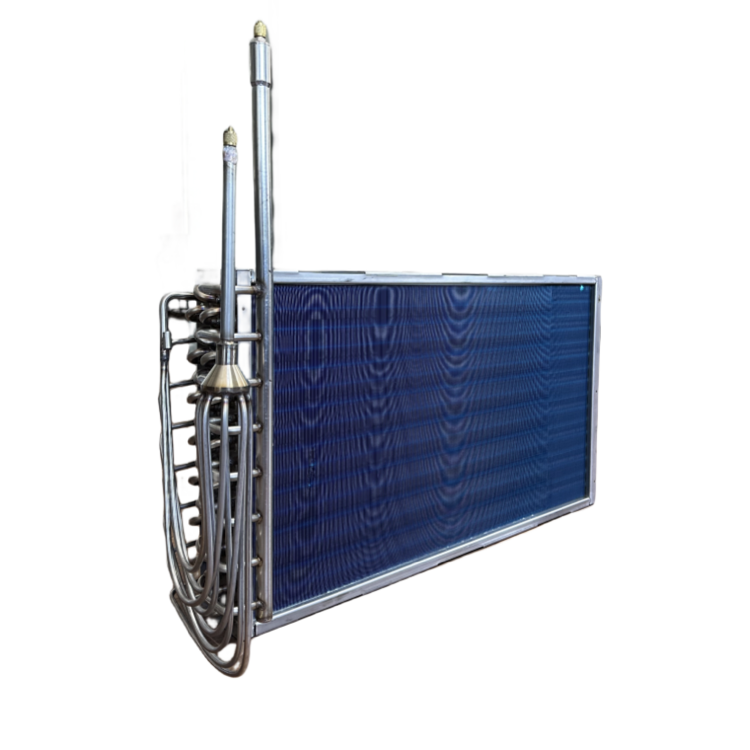

Model NO. | Customized | Application | Cooler, Condenser, Heat Exchangers |

Principle | Regenerative Heat Exchanger | Style | Corrugated/louverd/flat Fin Type |

Fins materials | Full Customization | Customized | |

Endplate | Galvanized/aluminum/Stainless steel | Specification | Customized |

Trademark | BENRUN | Origin | China |

Transport Package | Customized | Production Capacity | 100000pieces/Years |

MOQ | 10pcs ( sample is ok ) | Delivery time | 5-7 days for samples, 15-20 days for bulk production. |

Packaging & delivery

Packaging Details | Foam packed in inner machine,carton pack outside |

Port | Ningbo/ Shanghai |

In the world of dairy processing, where precision and hygiene are paramount, the choice of equipment plays a crucial role in ensuring product quality. The Galvanized Plate Stainless Steel Evaporator has emerged as a transformative solution, combining the durability of galvanized plates with the hygiene standards of stainless steel.

Advantages of the Galvanized Plate Stainless Steel Evaporator in Dairy Processing:

1. **Durability:** The galvanized plates enhance the structural robustness of the evaporator, ensuring longevity and reliability in the challenging conditions of dairy processing.

2. **Hygiene Standards:** Stainless steel's smooth and non-porous surface, coupled with its corrosion resistance, makes it an ideal material to meet the stringent hygiene standards required in dairy product processing.

3. **Versatility:** The Galvanized Plate Stainless Steel Evaporator proves versatile, accommodating various stages of dairy processing, from milk concentration to the production of dairy derivatives.

4. **Cost-Effectiveness:** The combination of galvanized plates and stainless steel offers a cost-effective solution by providing durability and longevity, reducing the need for frequent maintenance and replacements.

|  |

Home / Company / Products / Industries We Serve / Cases / News / Contact Us / Privacy Policy